Construction projects face a persistent problem: 35% of budgets vanish into rework and delays caused by design flaws (McKinsey, 2024). Mortenson, a $5B U.S. construction leader, turned this crisis into opportunity by deploying VR walkthroughs—not for flashy marketing, but as surgical tools for pre-construction problem-solving. Imagine spotting a misaligned HVAC duct in a virtual hospital corridor before concrete is poured. That’s the power they harnessed.

Rewriting the Blueprint of Construction Efficiency

While VR often conjures gaming or metaverse hype, enterprises like Varjo—featured in their documentary VR IS DEAD—prove its industrial teeth. Their headsets train F-16 pilots and simulate FAA-certified cockpits, blending precision with practicality. Mortenson adopted this same philosophy, shifting VR from a novelty to a profit-protection shield. Why matter? The average commercial project overspends by 14% due to coordination failures. Mortenson’s approach attacks this leak at its source.

For project managers, this isn’t about tech for tech’s sake. It’s survival. A single clash between electrical and plumbing systems costs $8,500 to fix post-construction—but pennies in VR. Mortenson’s pivot reflects a broader truth: industries demanding millimeter accuracy (aerospace, surgery, now construction) are adopting immersive tech not to escape reality, but to master it.

Precision Beyond Blueprints

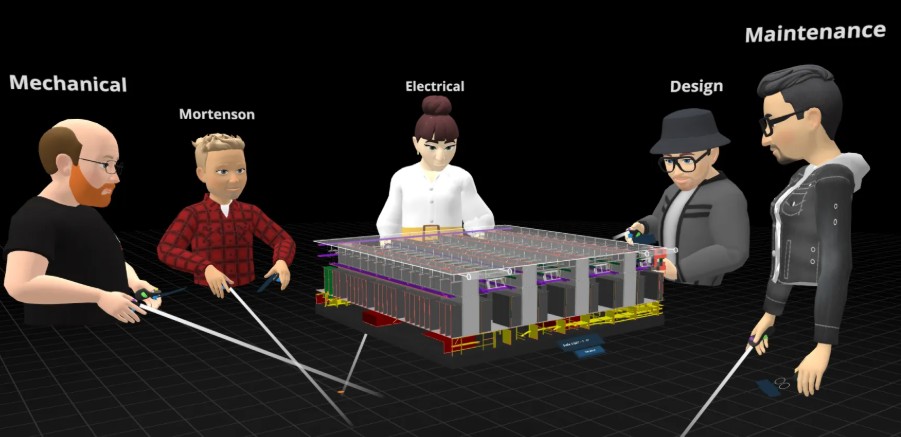

Mortenson’s VR strategy hinged on enterprise-grade hardware like Varjo’s XR-4 headsets, which offer 51 pixels per degree—matching human eye resolution. This granularity allowed teams to scrutinize 0.5mm structural tolerances in virtual models, a feat impossible with 2D blueprints. In one Denver hospital project, this precision identified 47 clashes between mechanical systems and structural supports pre-construction, averting $2.1M in rework. Unlike consumer VR, Varjo’s military-grade tracking (used in F-16 simulators) ensured spatial accuracy within 1cm, critical for aligning real-world construction with digital plans.

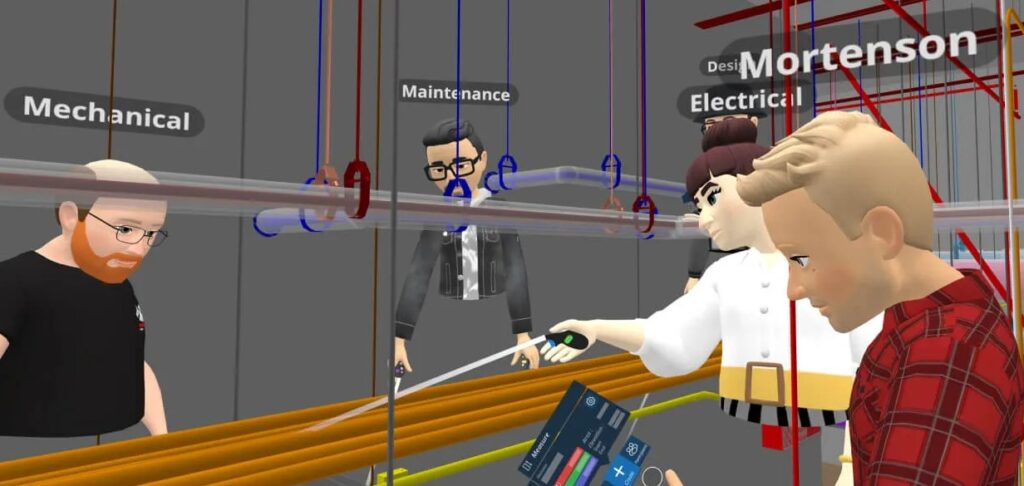

Their process transformed weekly coordination meetings. Subcontractors wearing VR headsets ‘walked’ through 1:1 scale models, flagging issues via voice commands logged in BIM software. A single 90-minute session resolved 83% of conflicts typically found during steel framing. Compare this to traditional methods: A 2023 Autodesk study found 68% of clashes are missed in 2D reviews, costing $12K per incident post-construction. Mortenson slashed clash-related delays by 41% across 14 projects.

Mixed reality passthrough—featured in Varjo’s tactical diorama simulations—became Mortenson’s secret weapon. Superintendents overlaid holographic models onto unfinished sites using MR headsets, verifying conduit placements against real-world rebar. At a Minnesota data center, this caught 19 misaligned anchor bolts before concrete pours, saving 137 labor hours. ‘It’s like having X-ray vision,’ said lead superintendent Mara Reyes. ‘We spotted a 2-inch HVAC offset that would’ve required cutting through finished walls.’

Unexpected savings emerged in change orders. Clients signing off on VR walkthroughs reduced post-approval design tweaks by 62%. Mortenson’s 2024 solar farm project used VR to simulate panel layouts across uneven terrain, optimizing spacing without costly land surveys. Result? A 22% reduction in material waste—$840K saved. Contrast this with industry norms: 73% of contractors report clients request changes after groundbreakings, inflating budgets by 9-15% (Dodge Construction, 2024).

But VR’s ROI isn’t automatic. Mortenson learned early that consumer-grade headsets caused motion sickness during 3-hour sessions, tanking productivity. Their fix? Varjo’s 120Hz refresh rates and industrial-grade ergonomics, adapted from FAA-certified flight simulators. They also trained teams to ‘read’ VR models differently—a steel beam that looks passable on-screen might reveal warped connections when viewed from beneath in 6DoF space.

The data speaks: Projects using VR saw 31% fewer RFIs (Requests for Information) and 19% faster approvals. At a Texas semiconductor plant, VR-enabled clash detection cut 11 weeks from the schedule—a $4.3M saving. Yet Mortenson’s biggest win? Cultural shift. As one project engineer noted: ‘VR made everyone—architects, electricians, owners—talk the same language. No more finger-pointing over flawed drawings.’

Building Tomorrow’s Profitability Today

Mortenson’s VR pivot reveals a universal truth: industries relying on precision—whether constructing hospitals or training F-16 pilots (as seen in Varjo’s documentary)—thrive when immersive tech bridges the gap between design and reality. The lesson? Proactive problem-solving isn’t just about avoiding rework; it’s about rewriting client-contractor dynamics. When stakeholders ‘walk’ through holographic models together, disputes over design intent evaporate—replaced by collaborative problem-solving.

For firms eyeing VR, start with high-stakes projects where errors carry six-figure consequences. Prioritize hardware with industrial-grade tracking (like Varjo’s FAA-certified systems) over consumer devices—motion sickness during a 3-hour site review tanks ROI. Train teams to interrogate models spatially: Can a welder access this beam? Does that conduit block future HVAC maintenance? These questions, answered pre-construction, turn profit leaks into margins.

The next frontier? Scaling VR’s cultural impact. Mortenson’s subcontractors now demand VR access in contracts—a shift mirroring aerospace’s simulator-driven workflows. As one electrician noted: ‘We’re no longer guessing; we’re building what we’ve already fixed.’ For leaders, this signals a reckoning: Clients will soon expect VR walkthroughs as standard, forcing laggards to eat others’ savings.